THEORY: Implicit vs Explicit - Introduction

Implicit Structural Solutions

Development

of the finite element method began in earnest in the middle to late 1950s for

airframe and structural analysis. By the late 1950s, the key concepts of stiffness

matrix and element assembly existed essentially in the form used today.

NASA issued a request for proposal for the development of the finite element

software NASTRAN (developed by MSC.Software) in

1965.

Steady State or Static Equilibrium (ΣF

= 0)

Force = Stiffness x

Displacement

In

actual practice, inverting the stiffness matrix to solve the system of

equations for displacement is highly inefficient. MSC Nastran uses a more efficient matrix

decomposition procedure rather than the matrix inversion method.

It is necessary to iterate the solution to be able to solve non-linear problems (using methods such as Newton-Raphson shown below, etc.) for many real-world problems. These nonlinearities can be associated with:

- Contact

- Material Behaviour

- Geometric Responses

The process by which an iterative implicit solution is obtained, is shown below:

Explicit

Structural Solutions

DYNA3D

was created in 1976 in order to simulate the impact of the Full Fusing

Option (FUFO) nuclear bomb for low altitude release (impact velocity of ~40 m/s).

DYNA3D

used explicit time integration to study nonlinear dynamic problems, with the

original applications being mostly stress analysis of structures undergoing

various types of impacts. It was further

developed for automobile crash test simulations to become primary explicit code

base today.

The history of Dytran (initially known as MSC.Dytran) is an evolution from DYNA3D to MSC.Dyna which was then merged with MSC.Pisces to become MSC.Dytran.

MSC.Dyna was the commercial version of DYNA3D offered by MSC which incorporated the explicit structural component built around FEM. DYNA3D also evolved into LS-DYNA and other explicit solvers on the market today.

MSC.Pisces was an explicit CFD hydrocode that solved fluid motion based on FVM (Finite Volume Method). Dytran introduced these two codes together to simulate the accurate interaction between both fluid and structural domains.

In release 2018 of MSC Nastran a new solver has been

introduced (SOL700), that comprises the explicit solver of Dytran. This has introduced advanced fluid-structure interaction directly to the

Nastran community within a single environment.

Dynamic Equilibrium (ΣF = ma+cv+kx)

Using

the Lumped Mass approach to de-couple the system of equations, there is no need

for a matrix inversion and a significant increase in computational speed can be attained. However, for stability purposes, it is required that the time step size is smaller

than the time it takes for a stress wave to pass through an element.

The process flow for an explicit time integration method is shown below:

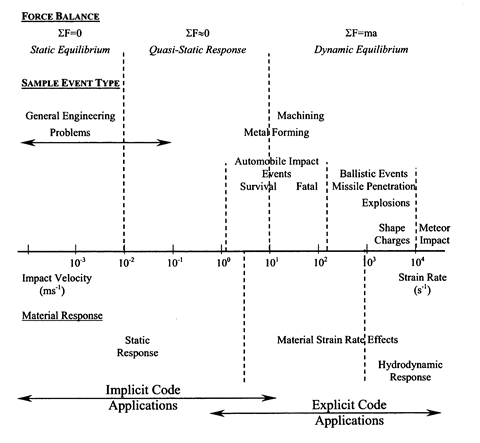

Choosing between Implicit and Explicit

Implicit is generally most efficient in solving for static and quasi-static equilibrium, therefore long duration nonlinear events would be suitable.

Explicit is more appropriate for high speed events, because the time step constrained by the event itself and the assumption of lumped mass. The use of reduced integration elements also mean that each step is considerably faster than implicit. A benefit of the small time step approach is that extreme nonlineararities can be handled by virtue of the relatively small change in state between each time step. Therefore it is more suited to highly chaotic or nonlinear events such as crash/impact and fluid-structure interaction from explosions and sloshing (to name a few).

From the graph below it can be seen that there is an overlap between Implicit and Explicit solutions, which will increase as computing power becomes more available. This enables Implicit solutions to use parallel computing to solve faster nonlinear problem more efficiently, while the same computing powers decreases the solving time for Explicit solutions, enabling longer duration events.