Customer Spotlight: Centre for Additive Manufacturing, University of Nottingham

Simulating Selective Laser Melting (SLM)

SLM is an Additive Manufacturing (AM) technology for producing end-use components by melting metallic powders using high density energy flux created by a moving laser source.

The team at Nottingham had clear motivation for researching what happens during the manufacturing process as the large thermal gradients result in transient and permanent residual stresses that may cause:

- Failure and/or distortion during manufacture

- Distortion upon removal from the build platform

- Overall reduction in part performance (e.g. reduced fatigue resistance)

Post Build Cracking

By simulating the process, it will identify the heat transfer during manufacture as well as the the distribution and magnitude of residual stress.

Modelling SLM however is very challenging and computationally

intensive due to the transient and non-linear nature of the process both across

time and space. This is because the model requires to capture the exposure of the fine laser (70 micron size) which raster across each layer (40 micron

thickness) across a relatively large part. Due to the extremely high

temperature gradients created by the exposure of the laser, an extremely fine

mesh resolution is required.

The capabilities offered in Marc in

particular adaptive meshing, time-stepping and extensibility, and the parallel

solver performance were vital for studying the process under different

scenarios.

Feedback received from the researchers detailed that Marc features around material models and the documentation of the user subroutines were powerful tools to model these specific manufacturing problems. The

post-processing capability offered in Python scripting language (PyPost) was also important to

analyse the results with higher efficiency.

To summarise: Marc was chosen as the software to investigate this problem for a variety of reasons:

- Competency dealing with highly non-linear manufacturing problems

- Scalability (DDM, parallel performance)

- Well documented and extensive list of User Defined Subroutines

- Fairly user friendly pre/post processor via Mentat

- Excellent technical support from local MSC UK office

- Weakly coupled transient thermo-mechanical analysis

- State variable model to track material properties for (powder, liquid ,solid)

- Thermal dependent thermal and mechanical properties + Plasticity Modelling

- Layer and element activation

- Adaptive time-stepping

- Local adaptive meshing

- Direct laser scan path and parameter modelling

- Extensive use of Fortran subroutines and additional C++ coupling for extra functionality

Temperature Distribution

State Variable Tracking

Powder = -1, Liquid = 0, Solid = 1

Von Mises Stress Distribution

But wait there's more!

They further investigated the effects of adding the next powder layer ontop for a 'real' 3D analysis:

Temperature Distribution

Von Mises Stress Distribution

Once the process setup was defined, more detailed analyses were defined for higher resolution scanning strategies. The figure below shows the highly transient behaviour of the process with the development of residual stress from the localised heat input.

Thermo-mechanical behaviour for 3x3mm area for Ti-6Al-4V

The transient animation showing the local adaptive remeshing that was required to fully capture the highly localised effects for a 5x5mm patch:

Temperature

Von Mises Stress

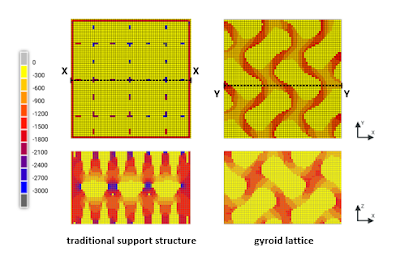

The investigation further progressed into the effect of lattice structures on the generation of residual stress.

Comparison of Steady State Effective Heat Transfer

Von Mises Stresss

Thermal History and State Variable Tracking

Lastly to end with the ultimate combination of all the analysis development from the above processes:

For more details, please take a closer look at the research paper here:

For more details contact:

Luke Parry

Centre for Additive Manufacturing

University of Nottingham

More to come!